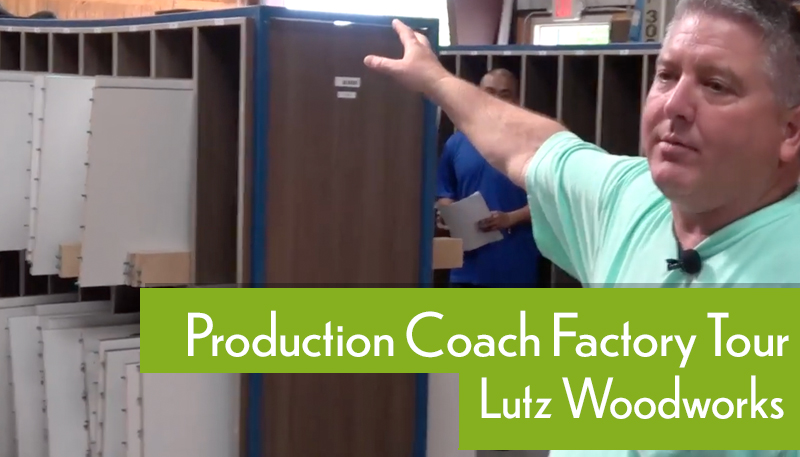

Production Coach Sorting

[layerslider id=”4″]

Reduce the amount of time (and money) spent searching for parts.

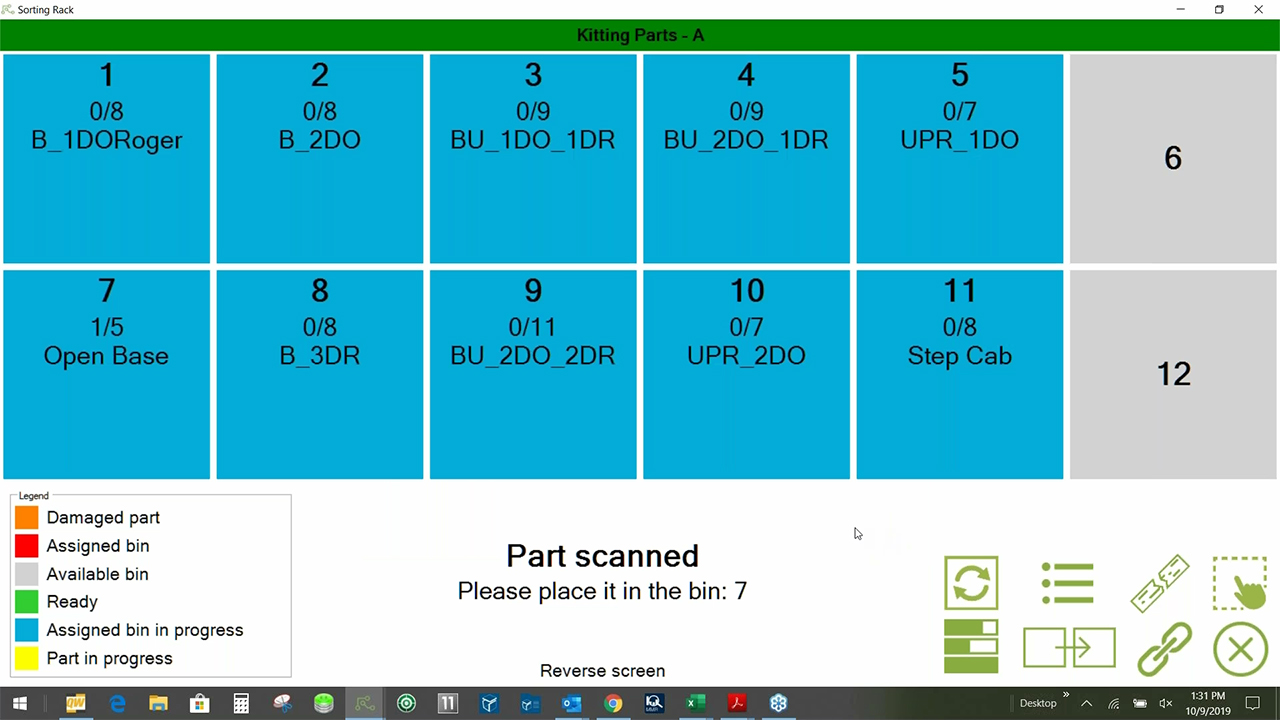

Sorting

A single barcode scan organizes parts by assembly and provides feedback for missing items. Assembly is notified of products ready to assemble. Sorting can be synchronized with other sorting stations: cabinet parts, doors/drawer fronts, drawer boxes, base assemblies, etc.

Compatible With

- Mobile Cart

- Wait until all parts of a project are sorted into 1, 2 or 3 mobile carts before being sent to assembly

- Square Footage Required

- Fixed Rack

- Put in/Pull Out

- Continuous Mounting

- Takes up less space.

All Blue

~ Ready To Sort

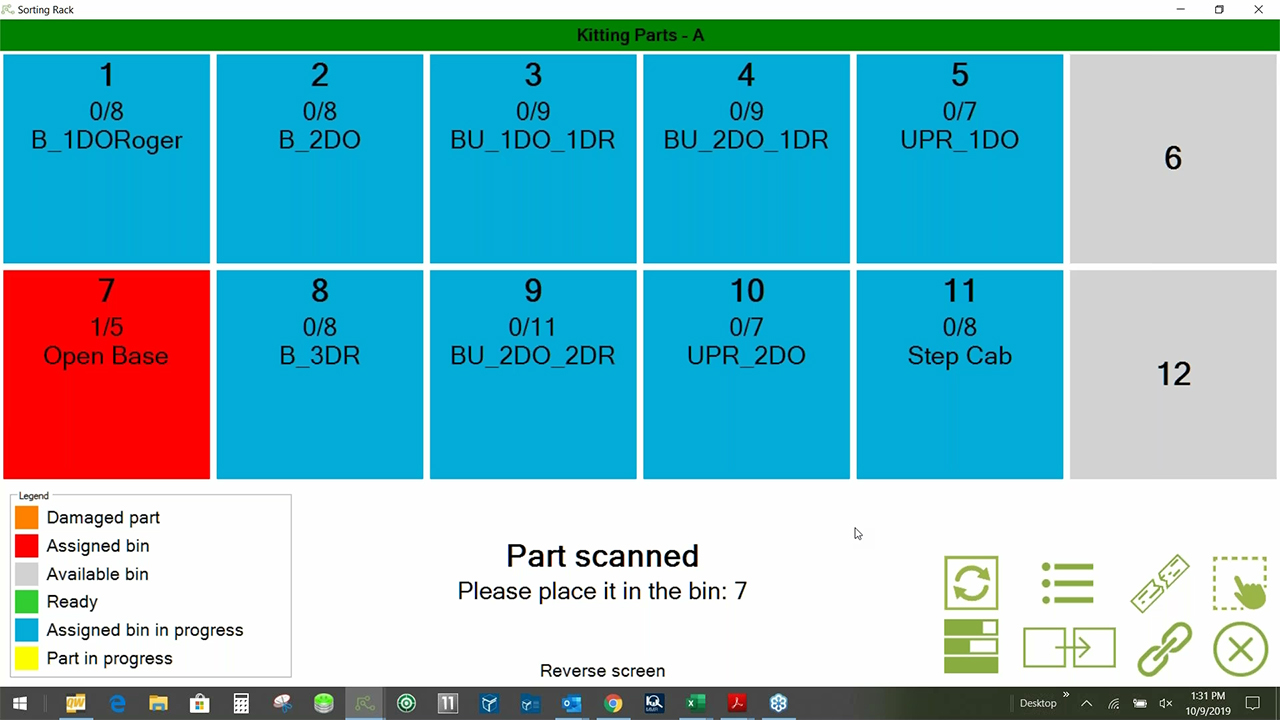

Red ~ Part Assigned Location/Bin

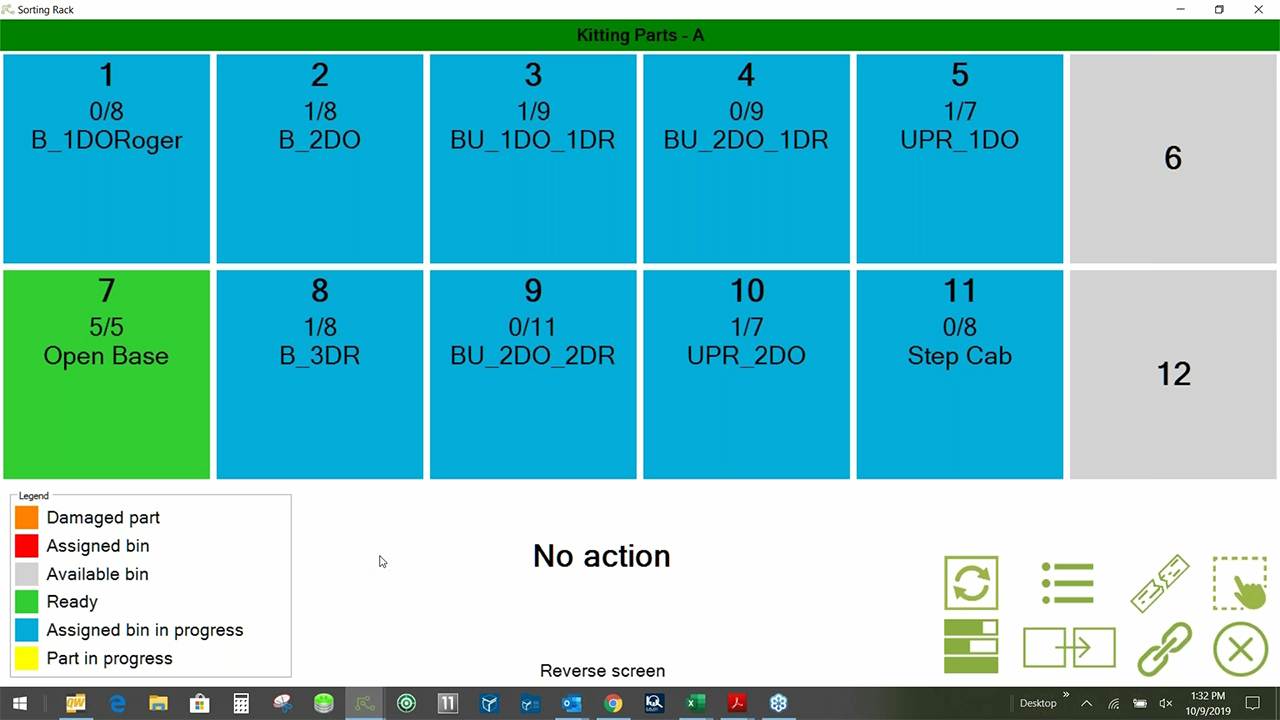

Green ~ Project Sorted Ready For Assembly

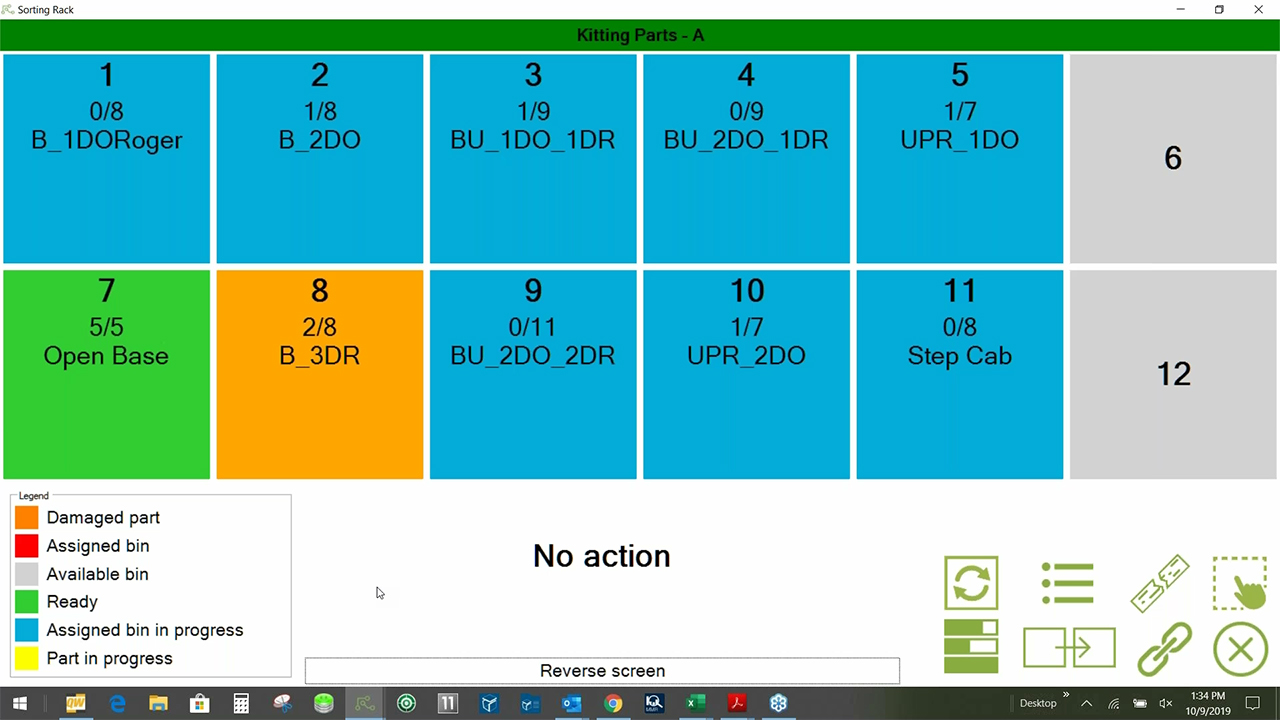

Orange

~ Damaged Part Alert

Production Coach Before

Production Coach After

Eliminates the need to search for parts

Clear visual of alerts and progress

Simplifies subsequent operations

Better management of space and resources

Production Coach – Proven Results

Our clients observed and confirmed numerous gains and improvements as early as the week following Production Coach implementation.