Posts by RSA Solutions

Biesse Fall Inside 2023

Woodpro Expo 2023

Stop by and check us out at Booth 315 at Wood Pro Expo Lancaster. WPE Lancaster is the only woodworking exposition and conference for professional woodworkers in the Mid-Atlantic and Northeast regions. Expo: October 12 & 13, 2023 Spooky Nook Sports Center, Lancaster County – PA Find Out More

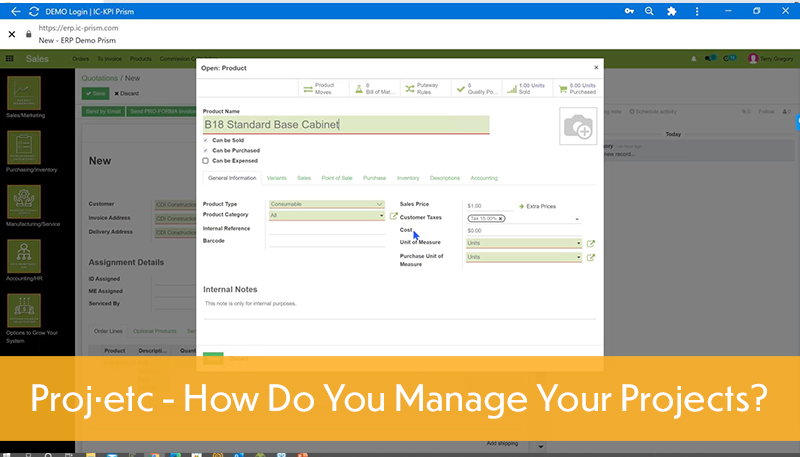

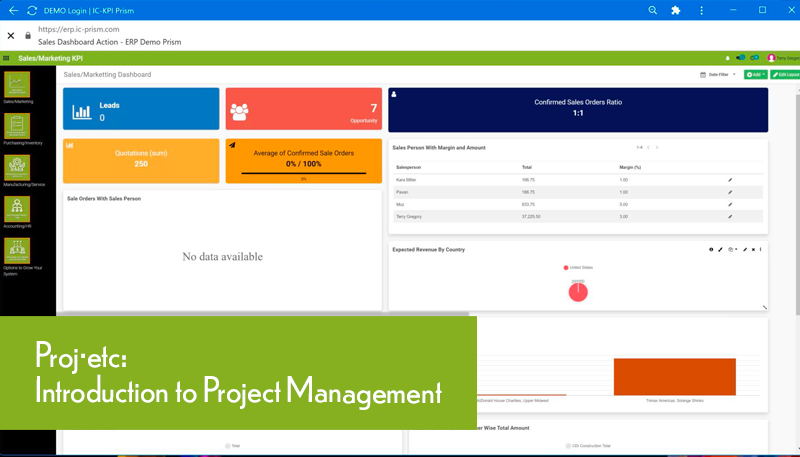

Read MoreProj.etc: Track Projects — Deliver Results

Introduction to PLANNING Assistant

2023 Closets Conference & Expo

Stop by and check us out at Booth 420 at The 2023 Closets Conference & Expo which is the ONLY national event for the closets and home organization industry. Conference: April 12, 2023 | Expo: April 13-14, 2023 Palm Beach County Convention Center | 650 Okeechobee Blvd | West Palm Beach, FL 33401 Find Out…

Read MoreFactory Tour at Masters Millwork

Join us for our Production Coach Factory Tour at Masters Millwork on May 25, 2023 at 10:00am to Noon. Lunch will not be provided. This Factory Tour is a rare opportunity to see a custom woodworking factory present the automation possibilities of Production Coach and the impact of that automation on production. This opportunity is…

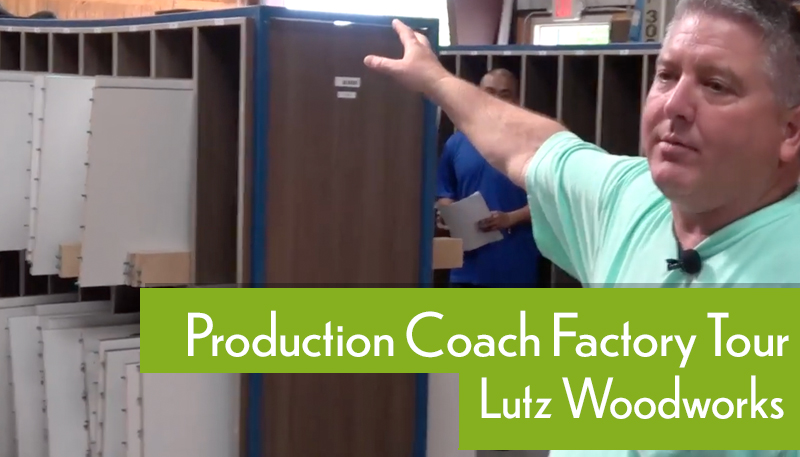

Read MoreLutz Factory Tour

Spooner Woodworks Success Story

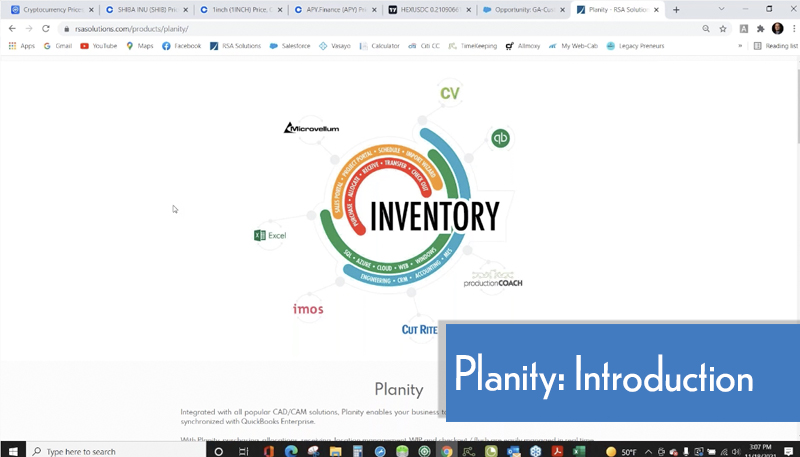

Planity Explainer Video

Proj.etc: Project Management

Production Management: Eliminate Bottlenecks

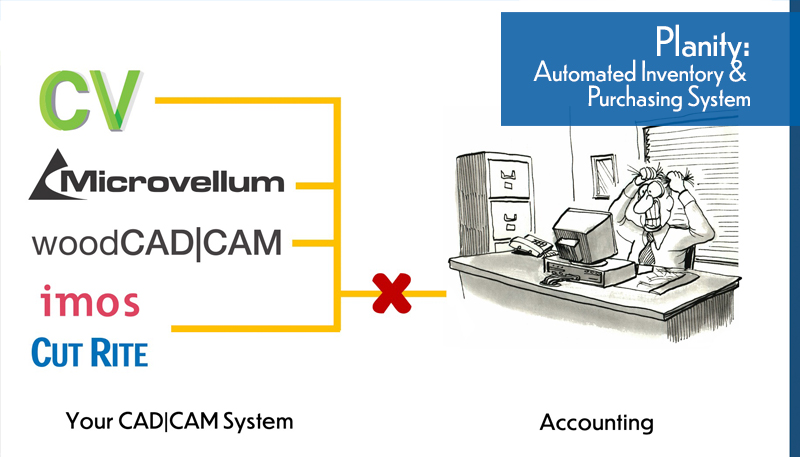

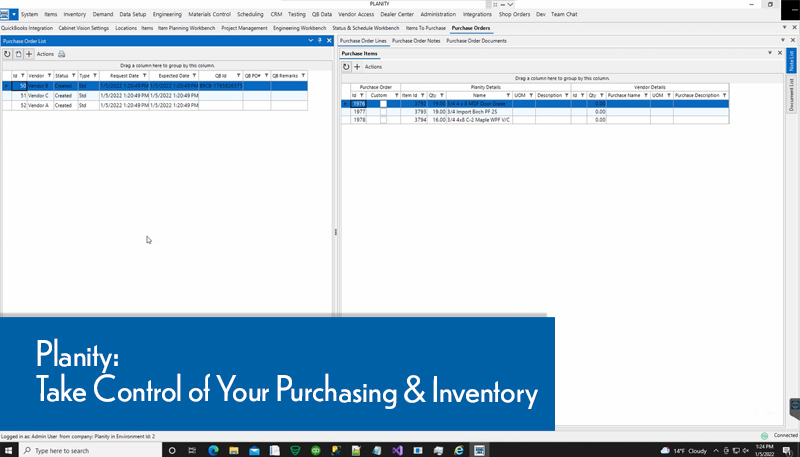

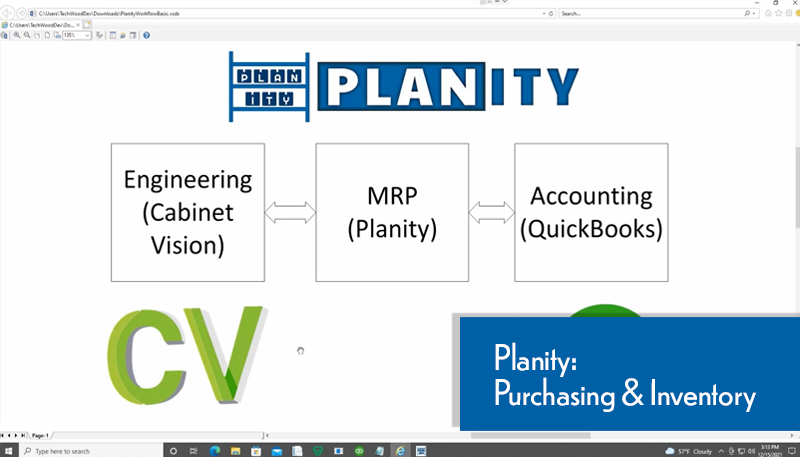

Inventory & Purchasing – Planity

Proj.etc: Intro To Project Management

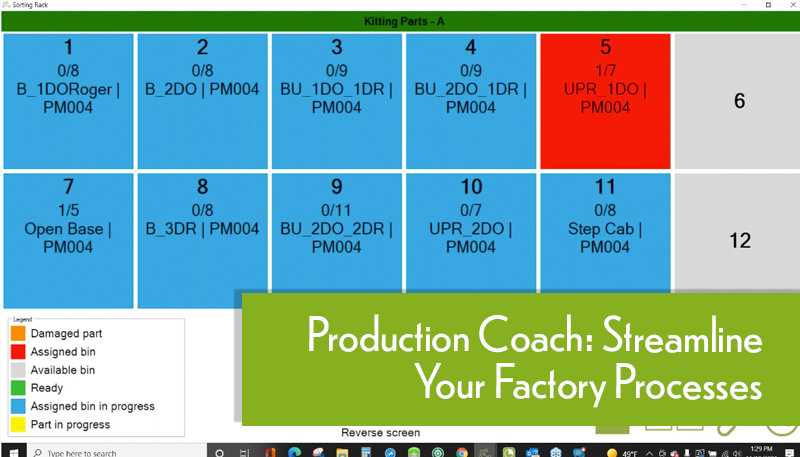

Webcast: Production Coach

Planity: Inventory & Purchasing Connected

Planning Assistant Overview

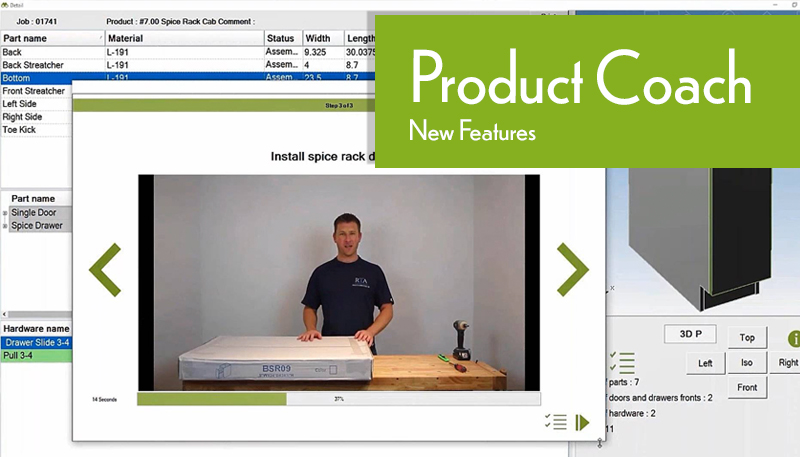

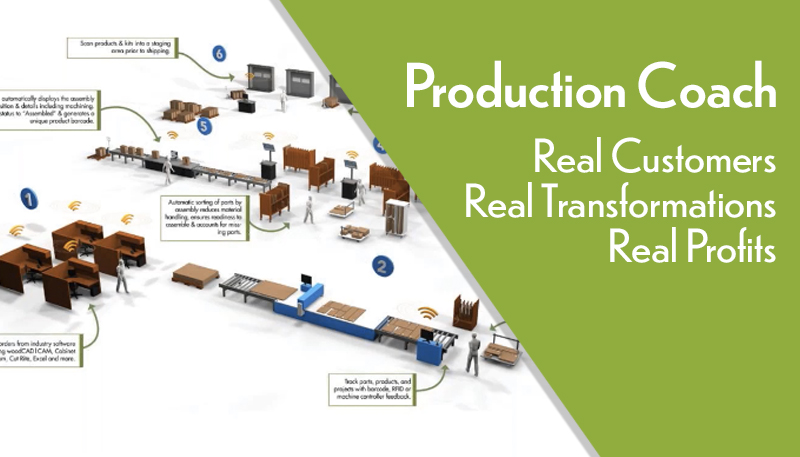

Production Coach

Planity Take control of your purchasing and inventory.

Streamline Your Production Process

Introducing Planity: Take control of your purchasing and inventory.

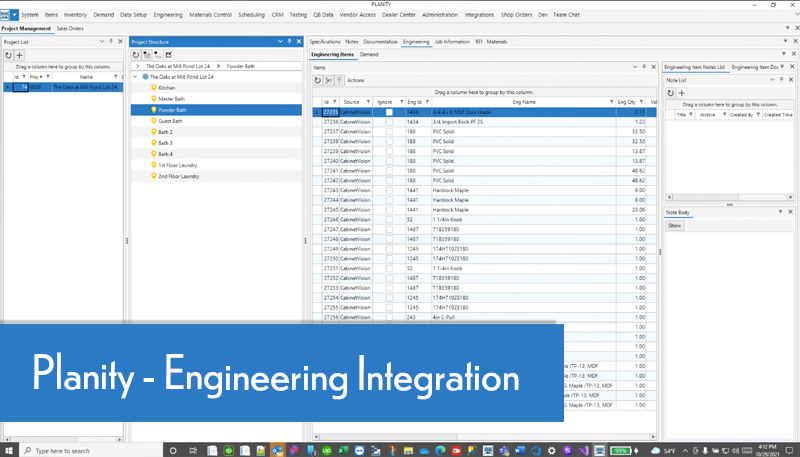

Planity – Engineering Integration

Ridge Crest Turns Inefficiency Into Profits

Ridge Crest Turns Inefficiency Into Profits Brian Boggs of Ridge Crest spoke with Shawn Maberry CEO of RSA Solutions during our recent webcast. Brian talked about inefficiencies they were experiencing before Production Coach and what Production Coach has allowed them to accomplish. Here is a small excerpt of Brian’s testimonial, please use the link below…

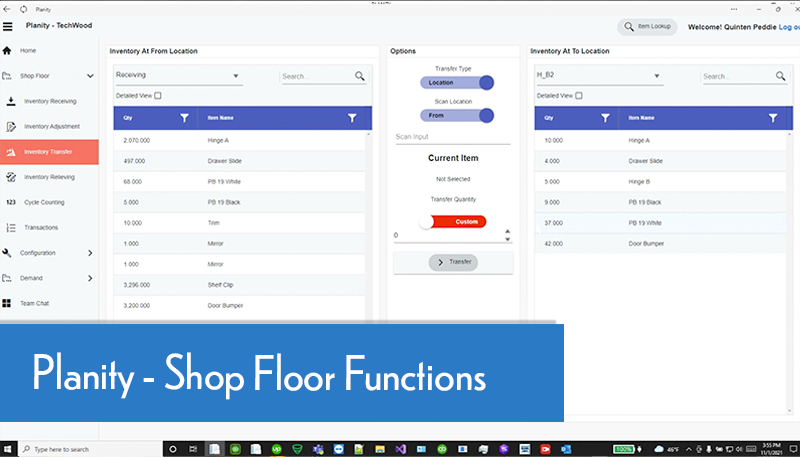

Read MorePlanity Shop Floor Functions

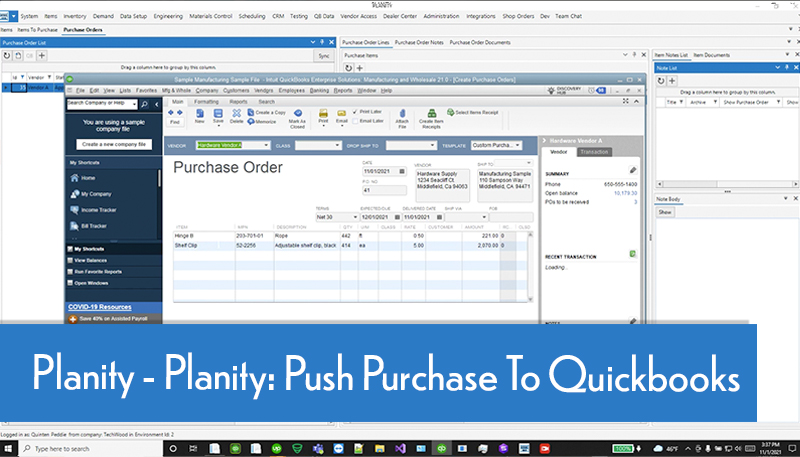

Planity: Push Purchase To Quickbooks

Pacific Crest

Production Coach Customer Success Story Pacific Crest

RSA Solutions Announces Roger D. Shaw’s Retirement

Lamar, MO. (August 16, 2021) – RSA Solutions, Inc. announces the retirement of industry icon, Roger D. Shaw. “Roger has served this industry these last three decades and his fingerprints remain on many current software solutions”, said current CEO and owner of RSA Solutions Shawn Maberry. Shawn Maberry went on to say, “Roger’s efforts along…

Read MoreAutomate Your Processes + Customer Success Story

Timberline Production Coach Customer Share Success Stories

2021 Customer Challenges

Production Coach Success Stories

Production Coach Customers Share Their Success Stories

Learn To Leverage Your Barcode

Production Coach: From The Developers, What is New and What is Coming

Production Coach Sorting In

Production Coach KPIs

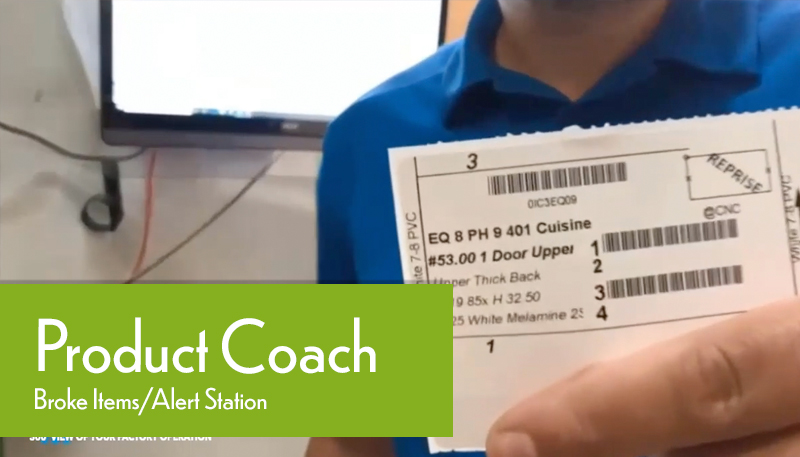

Production Coach Broke Items Alert Station

Production Coach Door Receiving

Production Coach CNC

Production Coach Dowel Edge Banding

Production Coach Kits Wrapping

Production Coach Shipping

Production Coach Staging

Production Coach Jobsite Tracking

Production Coach Assembly

Production Coach Drawers and Doors

Production Coach Sorting Out

Production Coach Hear From Current Customers & Industry Leaders

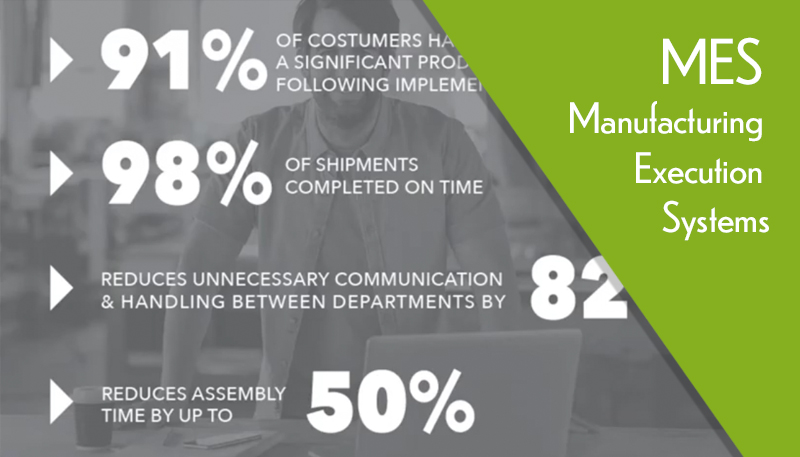

Manufacturing Execution System (MES) For Woodworking

Technological Shift: Essential For Factories Post-Pandemic Survival

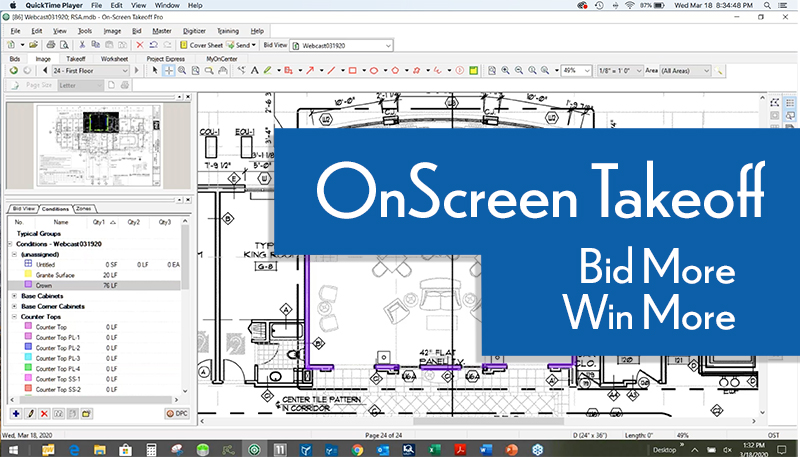

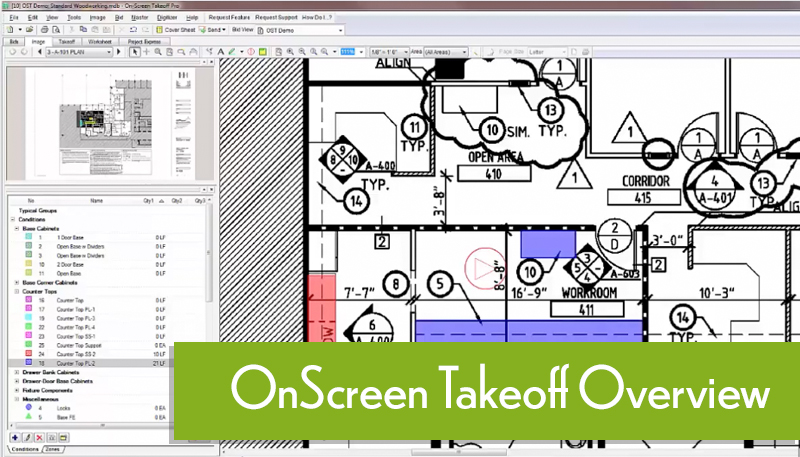

OnScreen Takeoff – Bid More Win More

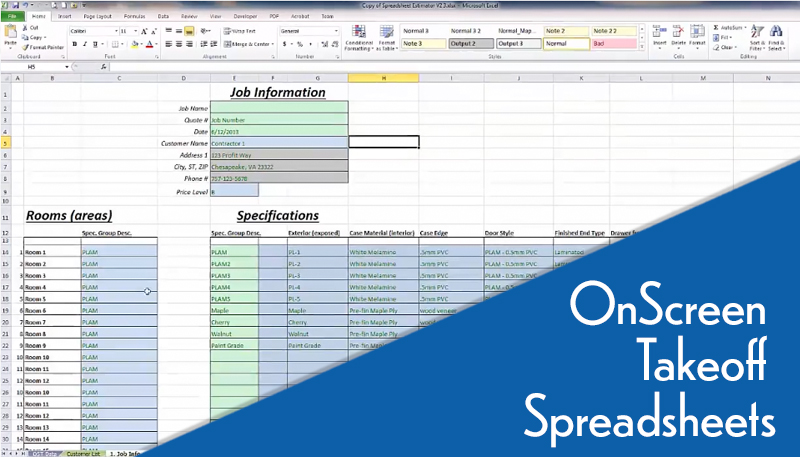

Estimator

Production Coach: Real Customers Real Transformations Real Profits

Homestead Cabinet & Furniture Custom, Discovers how to reduce material and labor costs

Homestead Cabinet & Furniture Custom, High-end Cabinet Manufacturer discovers how to reduce material and labor costs using existing design/engineering software and equipment. Homestead Cabinet & Furniture is a high-end custom cabinet shop located in Hyrum, Utah. Almost everything Homestead sells goes to prestigious interior designers. Homestead jobs are custom and almost every cabinet is different…

Read MoreFranklin Building Supply – Keeping Track of Parts

Production Coach Case Study: Franklin Building Supply Keeping Track of Parts when some of them are outsourced and need 3rd party processing Franklin Building Supply was founded in 1976 in Boise, ID and has 17 locations throughout Idaho and Nevada. Franklin is a vertically oriented company, supplying building materials as well as owning and operating…

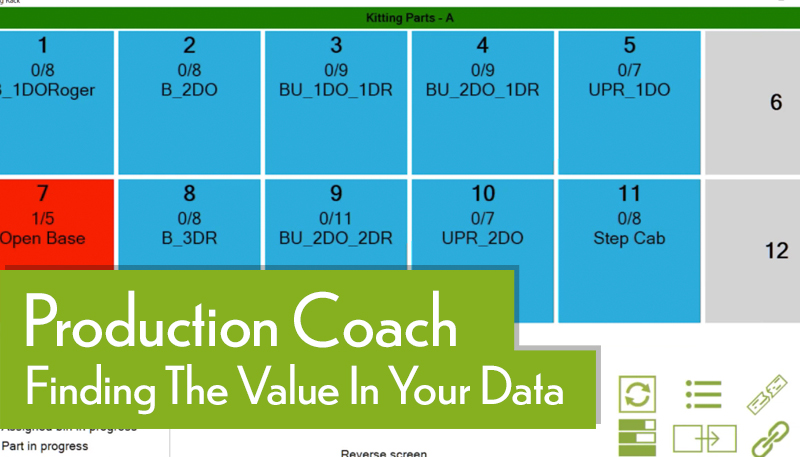

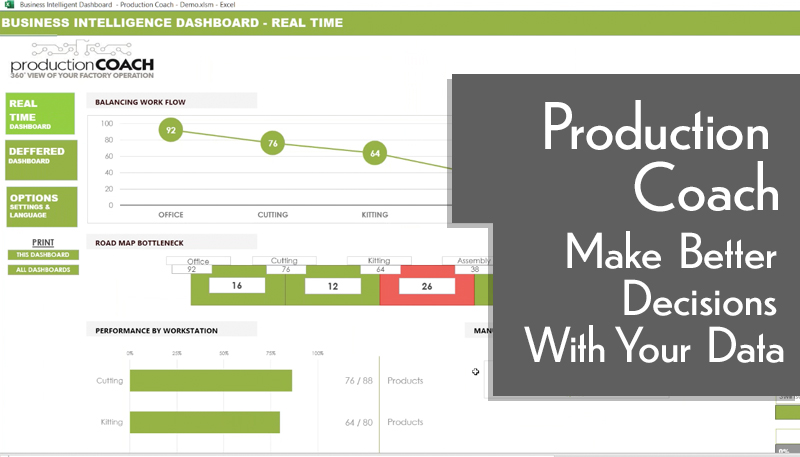

Read MoreProduction Coach: Finding The Value In Your Data

Production Coach Webcast

Former President of AWI Discusses Production Coach Integration

Greg Lutz former AWI President and owner of Lutz Woodworks in Wylie TX, talks about his before and after move to Production Coach. Factory Tour at Lutz Woodworks Read more about Greg’s move to Production Coach and how it has streamlined his workflow. View Article

Read MoreProduction Coach Streamlines Lutz Woodworks’ Workflow

Production Coach Streamlines Lutz Woodworks’ Workflow Implementing software with a Smart labeling system helps architectural woodworker sort out parts jumble. Lutz Woodworks of Wylie, TX, is reaping multiple rewards from its investment in Production Coach, an IWF 2018 Challengers Award-winning production management software from RSA Solutions. Within the first couple of weeks of implementing Production…

Read MoreMove To MES Timberline Webcast Excerpt

Move To MES Homestead Webcast Excerpt

Move To MES CIM Webcast Excerpt

Move To MES Franklin Building Supply Webcast Excerpt

Why and How Six Leading Woodworking Companies Moved to MES

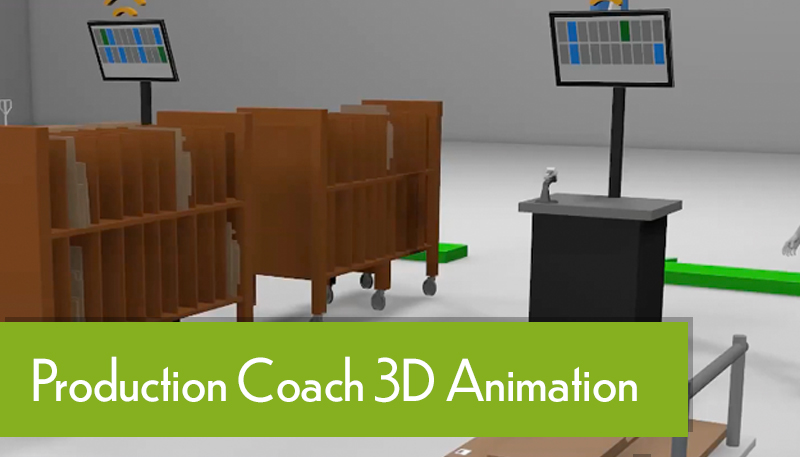

Production Coach Factory Tour

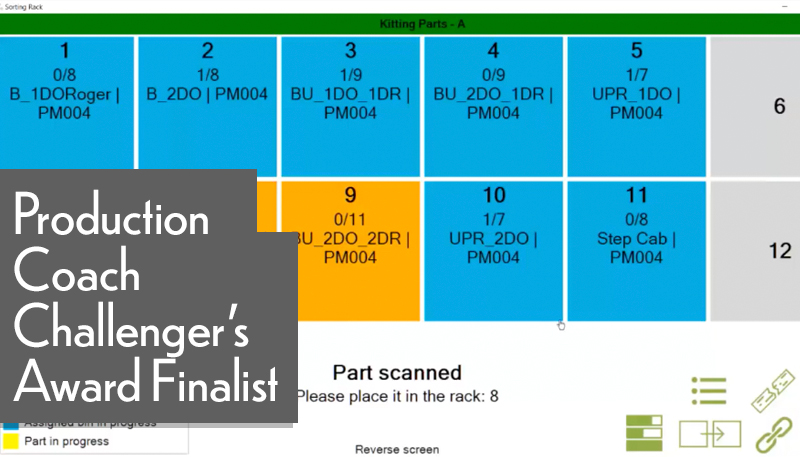

Production Coach IWF Challenger’s Award Product Review Webcast

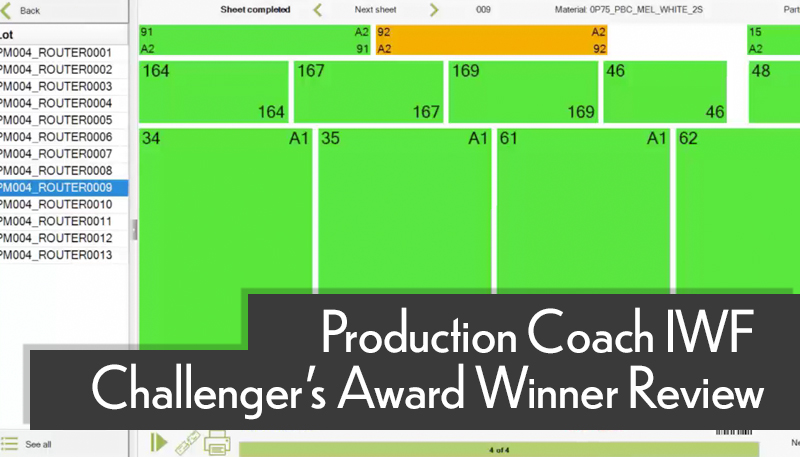

Production Coach: IWF 2018 Challenger’s Award Winner Video

Production Coach Manufacturing

Software Wins Major Award

2018 Challengers Distinguished Achievement Award® for Most Innovative Software Lamar, MO. (Aug. 29, 2018) – RSA Solutions’ Production Coach manufacturing software has just won the 2018 Challengers Distinguished Achievement Award® for Most Innovative Software at the International Woodworking Fair in Atlanta, GA. Production Coach provides a wholistic, 360-degree view of a manufacturing factory, from CAD/CAM…

Read More